Brazil’s infrastructure sector, encompassing public and private projects, is increasingly focused on operational efficiency through methods like kaizen (continuous improvement). A recent study analyzed five infrastructure projects (2013-2014) to quantify the ratio of value-added versus non-value-added activities on construction sites. The goal was to establish a baseline for future improvements, identifying waste and inefficiencies that hinder productivity.

Why This Matters: Infrastructure projects in Brazil, like those elsewhere, often suffer from hidden inefficiencies. Understanding where time and resources are lost is the first step toward streamlining operations, reducing costs, and improving project delivery. This study highlights that even companies with strong technical expertise may be unaware of the extent of waste in their routine processes.

Methodology: Multi-Momentum and Chrono Analysis

The study, conducted in partnership with Steinbock Consulting, employed two key analytical techniques:

- Multi-Momentum Analysis (MMA): This method involves taking periodic “snapshots” of shop floor activity, categorizing workers into three groups: those directly adding value, those performing necessary supporting tasks (transport, inspection), and those idle or engaged in unnecessary work.

- Chrono Analysis: This involves recording shop floor activity and quantifying the time spent by each worker on each step, calculating the proportion of value-added versus non-value-added time.

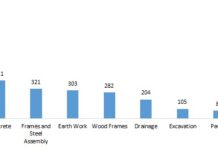

Both methods involved observations lasting at least 60 minutes, sometimes encompassing entire shifts. Sixteen different activities were observed across five projects: two intracity projects (analyzed as one), a highway, a railway, a pipeline, and a residential building.

Key Findings: A Shocking Amount of Waste

The study revealed that an average of 57% of project time was spent on non-value-added activities. This figure underscores a critical issue: even well-managed infrastructure projects are plagued by inefficiencies.

- Poor Preparation: The primary driver of waste was found to be inadequate shop floor preparation.

- High Transportation & Displacement: Projects involving large-scale movement (railways, highways) had lower value-added activity due to the sheer volume of non-transformative work.

- Lack of Awareness: Companies with strong capabilities were often unaware of the extent of waste in their daily operations.

The data illustrates that eliminating non-value-added activities could yield immediate productivity gains. The study suggests that management teams need to allocate resources to address these inefficiencies and promote a sense of urgency.

What This Means for the Future

This study offers a clear call to action: infrastructure companies in Brazil must prioritize waste reduction. The findings demonstrate that even low-hanging fruit – simple process improvements – can yield significant results. By quantifying waste and raising awareness, the study provides a foundation for more efficient project delivery and a stronger, more competitive infrastructure sector.

The study’s findings aren’t limited to Brazil. Inefficiencies in infrastructure are a global issue, and the methods used here – multi-momentum and chrono analysis – can be applied anywhere to identify and eliminate waste.

Ultimately, this research underscores the importance of continuous improvement and a relentless focus on value creation in infrastructure projects